Create sensible seals!

Water has power!

Water creates life and can in turn destroy everything.

Even a steady drip can severely damage a building envelope after just a few years.

Moisture doesn't just come from the outside, water pressing in from water reservoirs, pools, production and kitchen moisture must also be controlled or drained away.

This does not simply work by using a thicker wall or by opening a window.

As part of the Hanebutt Group, Hanebutt Bauwerksabdichtung GmbH deals with all these issues and solutions.

Waterproofing and structural waterproofing is a speciality for our experts!

Security and protection for your property

Car park roof systems

- Compact roof (car / lorry)

- Warm roof

- Inverted roof

- Car park decks without thermal insulation (type of load distribution slab / wearing surface: concrete / precast concrete slabs / concrete with asphalt)

Non-trafficable structural waterproofing

- Sealing against moisture in accordance with DIN 18 195 T4

- Waterproofing against non-pressing water in accordance with DIN 18159 T5

Kitchen sealing

- Commercial kitchens and catering

- Manufacturing and service industries

- Internal sealing

Good to know

We don't just come when it needs to be made new . We also offer repairs and maintenance.

All our employees who work for you are continuously trained and up to date with the latest sealing methods, materials science and technology.

You receive a high quality solution for your project with a guarantee promise.

Hanebutt roofs, for a lifetime.

What is structural waterproofing?

The basic principle of structural waterproofing is to prevent water damage to the building fabric. Such waterproofing can have different looks. However, they are particularly important in the renovation and new construction of basements, underground floors, bridges and tunnels, as well as on roofs and chimneys, for example.

As the active use of basements is becoming increasingly popular, the demands on finishing and waterproofing in new buildings and renovations have increased accordingly.

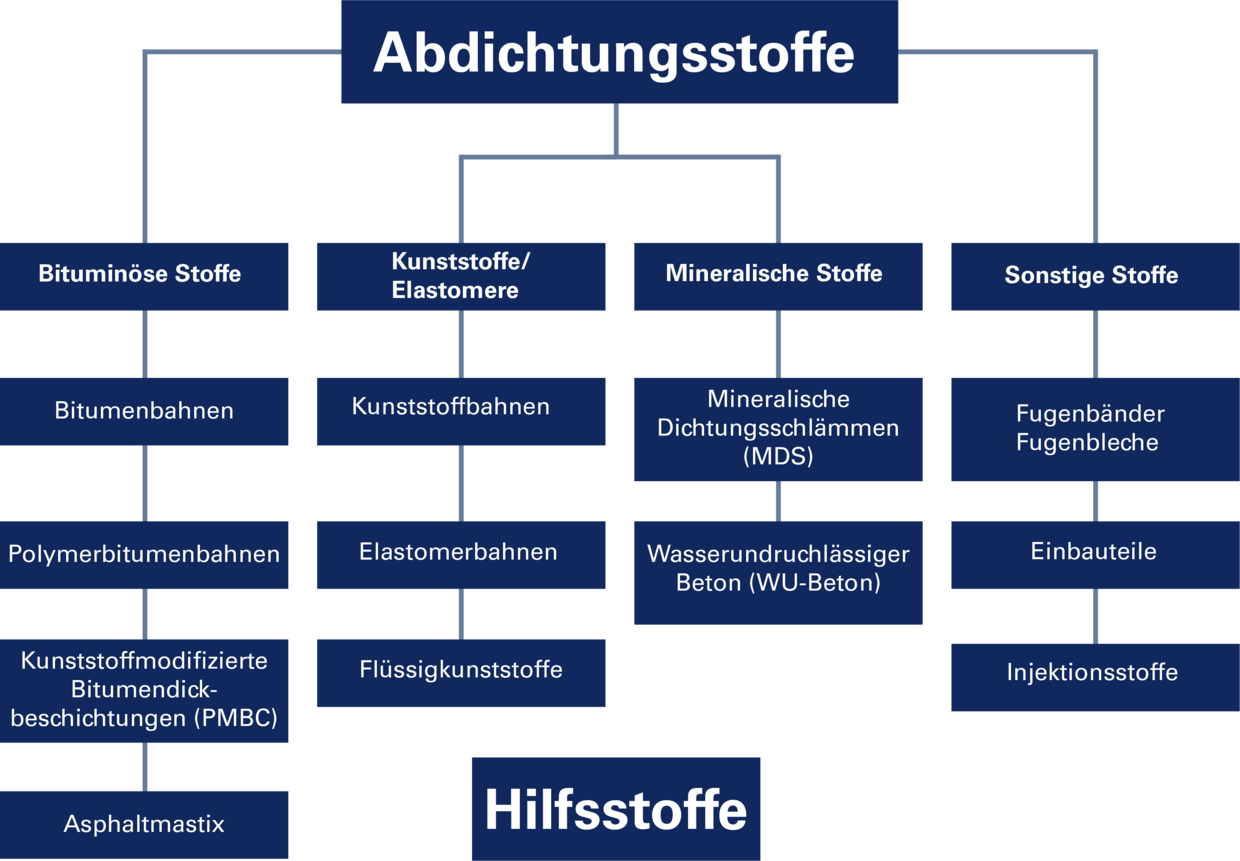

Materials for waterproofing buildings

Depending on the influence of water and the building substance used, various materials can be considered for waterproofing buildings. In addition, it is not only the influence of water that is decisive for the choice of the respective building material, but also whether it concerns underground parts of the building, parts in contact with the ground or parts such as roofs.

Another decisive aspect is the type of surface. For example, should a flat roof also act as a utility roof or simply provide protection? Are glass window domes installed on it or is it a straight surface? All these questions need to be clarified before you can decide on the right material. In principle, however, there is a wide range of materials available.

Procedure for waterproofing buildings

As with everything, professional execution is essential for long-term maintenance. This also applies to the waterproofing of buildings. It is particularly important to seal the plinth and foundation competently so that the entire building is guaranteed a long service life and continued stability.

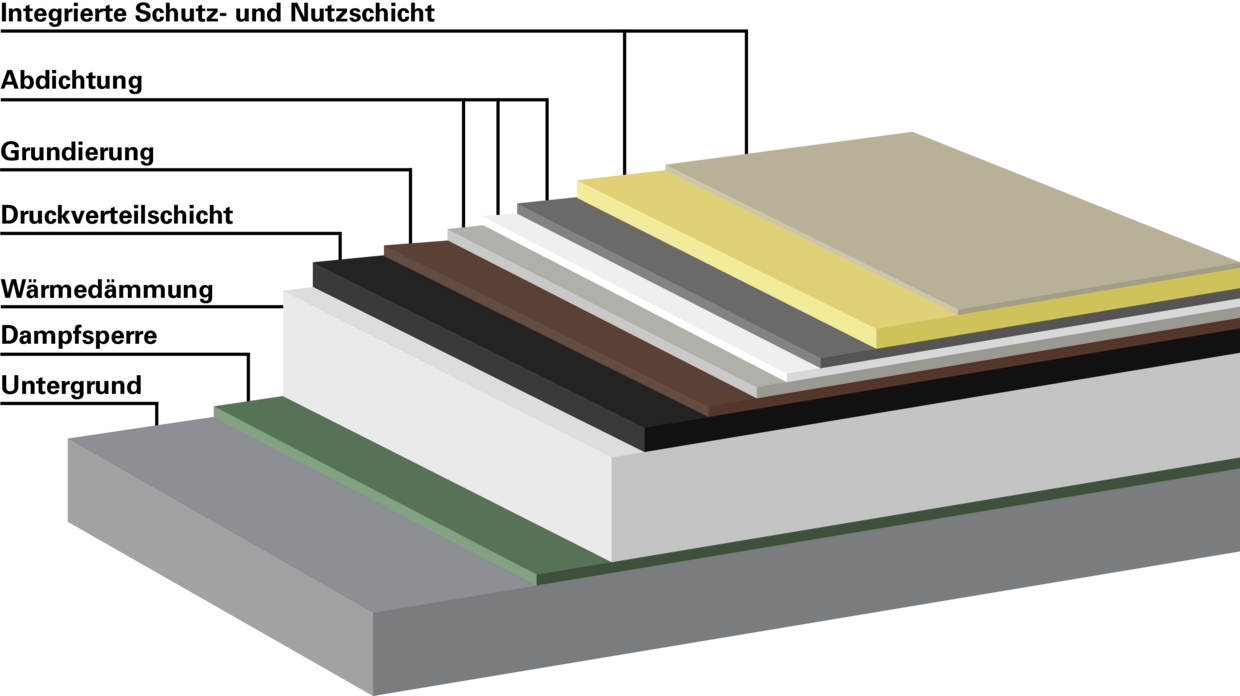

The material must also skillfully resist the water and form a stable barrier. The waterproofing procedure usually involves a number of steps, but always depends on the type of process and the underlying materials.

1. substrate pre-treatment, usually with a specific primer.

2. masking if necessary

3. respective sealing variant

4. external covering

Flat roof waterproofing

Tighter than tight - Hanebutt. However, in order to guarantee the best waterproofing for your flat roof, there are a few things to consider. Effective structural waterproofing depends on aspects such as

- Temperature fluctuations due to the prevailing climate

- unstable ozone content

- direct sunlight and UV radiation

- the possibility of storms and hail

- direct environmental pollution

- possible building movements

The main focus here is on temperature fluctuations. In contrast to underground parts of the building, where there is a prevailing risk of water accumulation, temperatures on the roof can reach up to 80 °C in midsummer.

So the choice of material and the workmanship are essential for reliable waterproofing. While good planning and execution are crucial, regular maintenance of the flat roof waterproofing is also required to guarantee the optimum protection of your roof on an ongoing basis.

Hanebutt not only offers professional execution, planning and advice in the field of structural waterproofing, we also offer regular maintenance appointments in the form of maintenance contracts. Once you have signed up, you no longer need to worry about the safety and moisture protection of your roof.

Maintenance measures for structural waterproofing

Even the best building waterproofing can have its weak points. That's why we at Hanebutt pay particular attention to the following sealing points during regular maintenance, as well as during installation:

- Roof edge and roof edge seals

- expansion joints

- Seam connections

- Wall coverings

- Breakthroughs

- Chimneys

- Vapour pipes

- Antenna passages

- Drainage installations

- skylight domes

By carefully inspecting these parts, Hanebutt guarantees that damage can be recognised and repaired at an early stage, before it has a major impact on the roof and on your finances.

Basement waterproofing injection method

Although we do not carry out injection procedures ourselves, we will be happy to advise you on the various techniques and alternative sealing methods. We will also be happy to forward recommendations to you if required.

There are three basic variants of the injection method:

1. curtain injection

Veil injection, also known as injection veil, uses a low-pressure gel that is injected into the ground directly adjacent to the building. This type of injection can be carried out "conveniently" without any further excavation work from the inside of the room in the respective basement rooms. The injected gel then bonds with the soil, creating an extensive external seal. This in turn acts as a protective shield, so to speak.

2. surface injection

Surface injection is similar to veil injection. Here too, surface sealing is carried out from the inside of the cellar room. Holes are also drilled into the cellar wall at certain intervals and the injection gel is then injected into them. This injection into the wall is carried out using low pressure.

This creates a seal in all pores and capillaries in the masonry through the so-called sealing veil. Here too, it is not necessary to work directly in the ground.

3. horizontal barrier

The horizontal barrier can also be created using an injection method. If everything has already been sealed vertically, the cross-section of the building also needs to be sealed. In the past, subsequent sealing involved a lot of work, but nowadays newer materials and methods make it possible to upgrade without pressure.

Here too, a gel is injected into the masonry by pressurised injection. This gel not only seals against water, but also provides lasting protection against pressurised water.

Metal structural waterproofing

Like wood, metal is a sustainable and versatile building material. The advantages of metal as a building material include its:

- Resistance

- fire resistance

- Resilience to strong temperature fluctuations

- Full recyclability

- Sustainability

An excellent building material that deserves a great deal of attention, and we at Hanebutt devote a lot to it. With an area specially developed for this purpose, we can offer our customers an unprecedented range of craftsmanship services such as consulting, planning and design, construction / production and installation, repairs and maintenance.

Building waterproofing made of PCI/liquid plastic

PCI or liquid plastics are another method of safely and efficiently sealing against water and moisture. Single-component polyurethane (PU) is a type of liquid plastic that can be applied cold and guarantees direct functionality.

This type of liquid plastic is particularly useful as it adheres to virtually all substrates. Further advantages of this liquid plastic are

- seamless waterproofing

- flexibility even at low temperatures

- elasticity and crack bridging

- solvent-free and diffusible

- can be applied from a temperature of +5 °C

- can also be applied by machine

Structural waterproofing made of bitumen

Bitumen and plastic membranes are now frequently used in the waterproofing of buildings and thus make a significant contribution to protection against moisture. The clear advantages of using bitumen are

- high perforation resistance

- extraordinary elasticity

- High dimensional stability in terms of elasticity

- Solid processing options

- in combination with carrier inserts: supporting elasticity and tear resistance

- above-average resistance to heat and cold

The use of the respective carrier units depends on the individual application. There are also possible combinations of plastic and bitumen seals.

Comparison of PCI, bitumen and metal

Basically, there are many designs and basic requirements that must be observed in each case. The choice of waterproofing material depends on the respective conditions. The following aspects are particularly essential, which in turn depend on the conditions on site, such as

- the resilience and flexibility of the material

- the amount of moisture

- the temperature fluctuations

- or the reaction of individual substances in the environment

Depending on these individual aspects and taking into account the relevant DIN standard, a decision is then made as to which structural waterproofing is suitable.

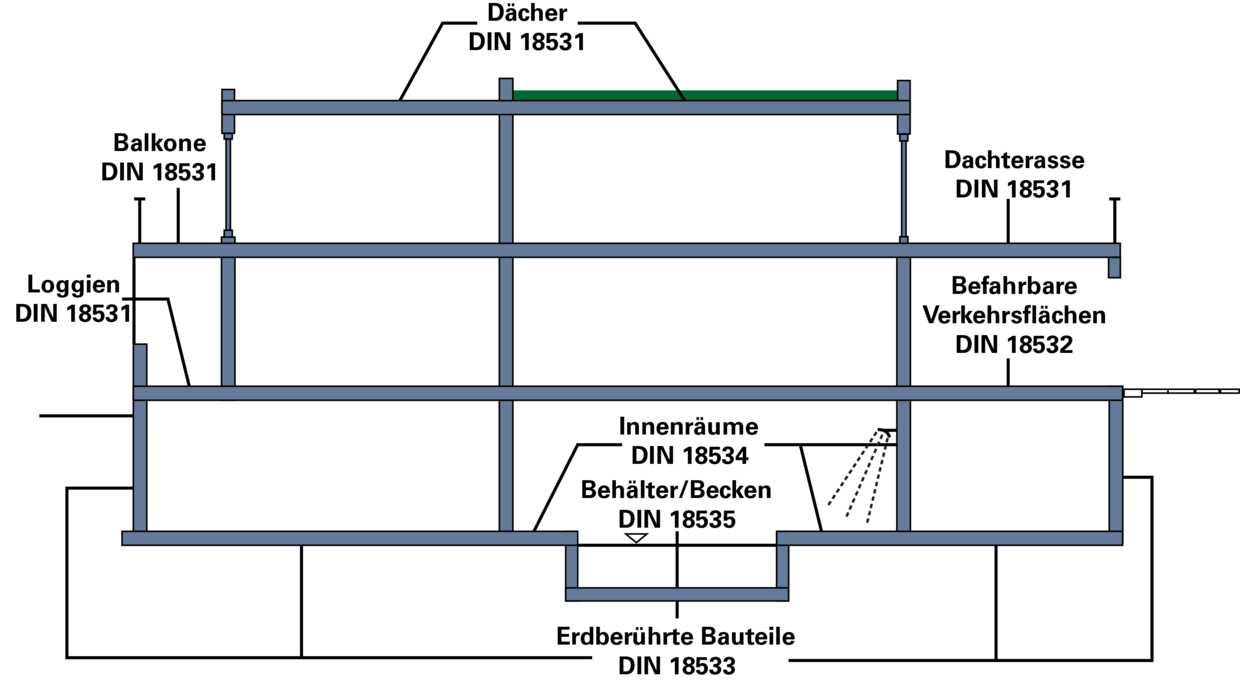

DIN building waterproofing

While DIN 18195 used to cover all relevant standards, since 2017 it has defined terminology and implementation standards. The DIN 18531 and 18535 standards are the most relevant in building waterproofing, as they cover various areas of buildings.

Depending on the effects of moisture and the respective effects of water on individual building materials, the materials and methods to be used for waterproofing are specified. A distinction is also made as to whether this involves underground rooms such as cellars or above-ground parts such as roofs.

Giving you an overview of various standards, all those applicable to the waterproofing of buildings are listed here:

- DIN 18195 - Terminology relating to the waterproofing of buildings

- DIN 18531 - Waterproofing of roof surfaces

- DIN 18532 - Waterproofing of buildings with concrete traffic areas

- DIN 18533 - Waterproofing of structures in contact with the ground

- DIN 18534 - Waterproofing of indoor structures

- DIN 18535 - Waterproofing of buildings with tanks and basins

A distinction is also made between the occurrence of water in:

- Non-accumulating seepage water, which drains away by itself without major construction work, depending on the respective soil conditions.

- Accumulating seepage water, which is caused, for example, by clayey ground due to accumulations of water that do not drain away. Drainage or multi-layer sealing is recommended in this case.

- Water pressing from the outside, which exerts permanent water pressure on the building structure. This type requires more extensive waterproofing of the building. In addition, waterproofing should ideally be carried out directly during new construction rather than afterwards.

- Water pressing from the inside, which describes wet surfaces on the inside. Floor drains, pipework, gutter drains or similar can also provide a remedy here.

In principle, however, these are only relevant for the tradesmen themselves. However, if you would like to find out more about the individual standards, you can read more about them on the website of the German Institute for Standardisation.

Structural waterproofing with Hanebutt

We can do big things, but we can also do small things and are at your side whenever you need our support. With Hanebutt, you receive the full service package and an all-encompassing range of services for private customers, as well as in trade, industry, administrative buildings, shopping centres and exhibition and representative buildings.

We provide first-class work for building plumbing work such as

- roof drainage via gutters and downpipes

- the construction of metal roofs made of zinc, copper, aluminium or steel

- the design of chimney cladding and metal façades

- the erection of steel structures, steel composite structures and steel skeleton structures

- External drainage for small individual houses and functional buildings

In addition, Hanebutt's metal experts also take care of sound insulation installations on and in your building systems on request.

FAQ

The basic task of structural waterproofing is to protect building materials from the penetration of moisture. Among other things, structural waterproofing is also required for containers.

The waterproofing of foundations, plinths and roofs is essential in order to provide the building with a secure base and guarantee a long service life. As the durability and safety of a building stands and falls with the quality of the waterproofing, it is crucial to pay attention to professional workmanship such as that provided by Hanebutt.

Not only the design, but also the regular maintenance is relevant and should not be neglected. Hanebutt also offers maintenance contracts for the ongoing upkeep of your building.

Structural waterproofing is always relevant as soon as moisture can penetrate the building or the building fabric from the outside and damage it. In principle, both roofs and underground parts of buildings such as cellars should therefore be waterproofed.

However, structural waterproofing is also used, for example, in the construction of tunnels or bridge structures.

With regular maintenance, a professionally waterproofed basement should remain watertight for around 50 years. However, the maintenance of the seal depends on external conditions, the amount of water, the materials used and the implementation, as well as the building material itself.

The costs of waterproofing a building depend heavily on the underlying DIN standard, the materials used and the circumstances on site. Please contact Hanebutt for an exact cost calculation. The costs can be determined precisely with an exact survey.

Structural waterproofing should extend at least up to 30 cm above the top edge of the ground. There should also be no gap between the base waterproofing and the building waterproofing in contact with the ground.

As structural waterproofing is essential for the safety of the building and is subject to certain regulations and standards, it may only be carried out by professionals.

Such waterproofing is often carried out by bricklayers, reinforced concrete constructors, wood and building preservationists, structural waterproofers or, as in our case at Hanebutt, roofers.

The approach to building waterproofing depends on many factors. For example, whether the waterproofing is to be applied from the inside or outside, the materials used and the building fabric.

It also depends on what is being waterproofed, i.e. whether it is an underground part of the building, a roof or a submerged object, whether it is a renovation or a new building and whether or not a primer is required.

Please feel free to contact us for more detailed information. At Hanebutt, we provide you with professional and appropriate advice so that you receive the highest level of service.